Accurate, real-time feed

inventory makes for timely and informed decisions.

Bin scales for all types of livestock farming

Feed constitutes 65% of live production cost

Improving feed management is critical to reducing costs in poultry production. Bin scales are an important tool for optimizing this process. In fact, they are the only sensor accurate enough to determine the feed consumption of individual birds, not just the entire flock. With this accurate data, you can make informed decisions about your flock management, reduce waste and avoid overfeeding, resulting in significant cost savings.

Feed Bin Scales

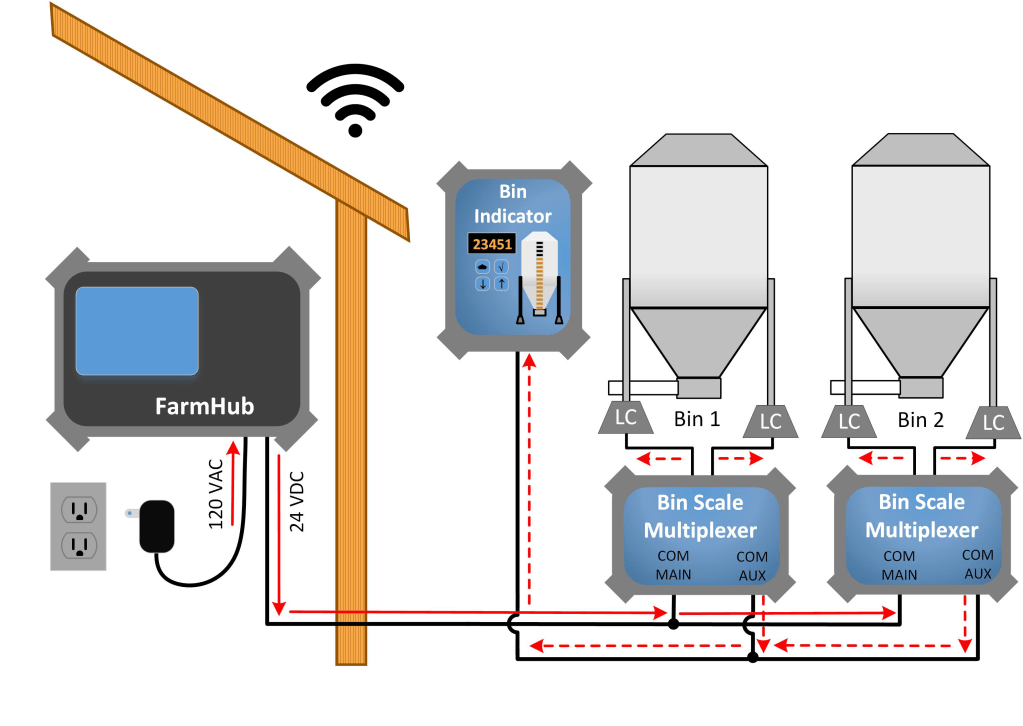

The Intelia Feed Bin Scale product line includes several options, to make the system as simple as a standalone feed bin scale and as extensive as a true feed management system. When connected to Compass Farm Data Management Software, they allow you to take control of your feed, wherever you are.

Load Cell

- Robust – custom design

- Ease of installation on new or existing feed bins – no concrete drilling

- Integral lifting system

- Built-in compensation against wind-induced vibrations and temperature fluctuations

- Capacity of 10,000lbs per load cell/leg

- Built-in lightning protection.

Bin Indicator

- Displays feed level and inventory in real time

- Large numeric, easy to read display

- Simple calibration process

- Can be installed inside/outside

- Can display the inventory of up to 4 near-by feed bins per bin indicator.

FarmHub

- Connection of up to 4 feed bins and display of additional feed-related data: Feed level, daily consumption and feed inventory history

- With the optional cellular package, FarmHub can transmit data to Compass Farm Management Software

- The hub is ready to receive other sensors.

All of our bin scale equipment is:

Simple and user friendly

Low maintenance, easy to calibrate, 5-year warranty on mechanical parts, 2-year on electronic and 1-year against lightning (properly grounded bin).

Patented

Patented load cell configuration, installation and lifting system.

Easy to Install

The Intelia feed bin scale does not require lifting the bins or drilling concrete. This can save up to 50% in installation time/cost!

Easy to Retrofit*

Available for the common “W-shaped” leg profile found on poultry farms, for 4, 6 or 8 leg bins. *On most silos.

The Right System for Everyone

Feed Mill

ACCUSMART FEED BIN SCALE

- Standalone system

- Optimizes feed mill production, scheduling and delivery

- Eliminates feed outages and out of sequence feed deliveries

- Advanced planning for inclement weather and other disruptions

- Reduces the amount of haulbacks and end-of-flock feed transfer.

Grower

ACCUSMART FEED BIN+

- Standalone system

- Tracks feed intake and feed history

- No more bin climbing with inherent risk

- No more “Mallet” work or guestimation

- Eliminates feed outages and subsequent negative impact of growth performance.

Integrator

ACCUSMART FEED BIN DATA+

- Connected system

- All the benefits of the Feed Mill with the ability to add additional sensors and cross analyze for more insight

- Improves bird weight forecasting

- Keeps flock advisors focused on animal husbandry instead of managing feed.

Become a Dealer!

Are you interested in becoming a supplier of hardware solutions for the poultry industry? Complete our form to get more information.